Basic Specs

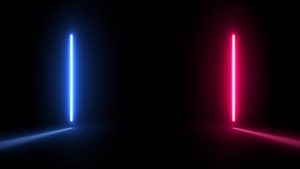

Adagio 2.0 will be similar in function as the Adagio 1.0, but will be larger, measuring approximately 2x2x3 ft. The rotation rate will be broader, going from 0 rpm up to approx. 5 rpm. The external shape will be cylindrical using sheet metal with a black powder coating (or similar). Both the power on/off and rotation speed can be controlled using a remote control. The primary viewing will be from the front side. A viewing port will also be available from the rear but of course will be the “opposite” curve position as seen from the front. The lighting will be similar to 1.0 with a solid red line at the center with blue an ambient glow to highlight the non-central visible part of the curve. Standard household AC outlets can be used to power the unit.

Cost Estimate

We will be doing the 2.0 build “at cost”, meaning Max and I will volunteer our time and Max won’t charge for machine use and shop overhead. I.e., estimated costs shown are for materials only. Receipts of component costs will be attached and sent to THE FIRE for each phase shown below.

NOTE: Cost and schedule shown below are considered to be estimates only and subsequently are nonbinding. We will do our best to hit and/or do better than all cost and schedule targets shown.

power strip | $ 14 |

on/off remote control | $ 16 |

slewing ring | $ 130 |

dc gear motor | $ 63 |

friction drive roller/pulley 4″ | $ 52 |

speed control with remote | $ 46 |

ac to dc | $ 40 |

custom neon light | $ 200 |

acryic light shields frosted (2) | $ 100 |

cylinders (2) aluminum | $ 264 |

acrylic sheet 2 halves support | $ 88 |

powder coating | $ 120 |

Misc materials | $ 100 |

crate build and shipping | $ 125 |

TOTAL | $ 1,358 |

Phase I

Detail design – Completed.

Phase II

Rotation Drive Components. In this phase we will purchase the motor drive components to make sure they meet our requirements and integrate with each other as anticipated. If all components work as expected, we can then design the mounting brackets. The motor mount design will be modified as necessary. The primary component platform bracket can be designed and cut. In this phase, we purchase the sloughing ring component which is the key component that drives the overall dimensions for the whole unit. It seems appropriate and perhaps even poetic that a component that is effectively a circle is the cornerstone that defines all other dimensions for the 2.0 build. This part is effectively the “center of the universe” for adagio 2.0.

Slewing Ring

COST: $361

Phase III

Neon Lighting. We will work with Neon Art and Design (local) to build the internal lighting component.

COST: $300 (est)

Phase IV

Build inner and outer cylinders (inner cylinder with sine curve). Detail design and CNC machine cuts of inner and outer cylinders to 2 x 2 x 3‘ specifications. We are anticipating using aluminum sheets as the source material.

COST: $452

Phase V

Adagio 2.0 Prototype (mockup) assemble, and test. Assemble all components of adagio 2.0 with temporary fastenings to allow for easy disassembly and subsequent powder coating. test, mechanical functionality to the extent possible and ascertain visual artistic/aesthetic goals and functionalities have been actualized.

COST: $0

Phase VI

Powder coat the visually exposed parts. Disassemble the adagio 2.0 mock up as per the previous phase. Prepare parts for delivery to powder coating facility. This will need to be outsourced to a local powder coating company.

COST: $120

Phase VII

Final assembly and test. Reassemble components that are now powder coated. Lock down all components with permanent fastenings. Do final testing of all components. Prepare for shipping.

COST: $0

Phase VIII

Crate and ship.

COST: $125